Color Management

COLOR

Management

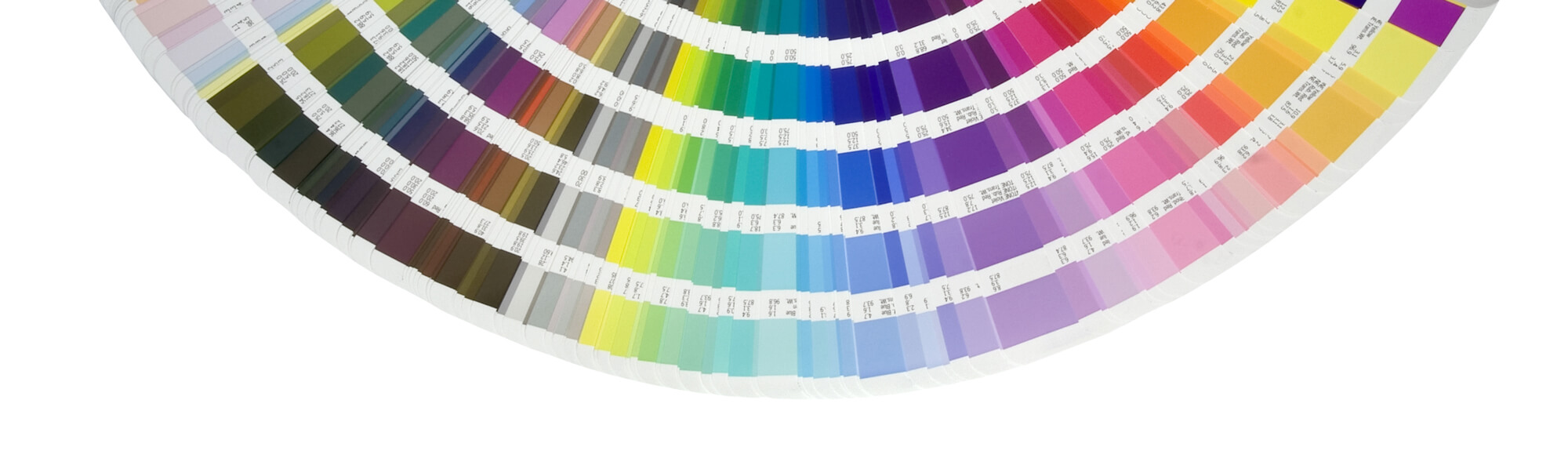

Your colors are a big part of your identity. Having color consistency on every package, on every substrate, and through every run isn’t a matter of being nitpicky, it’s a quality standard that is central to maintaining the integrity of your brand.

When it comes to Color Management, not all providers are created equal and we don’t take color lightly. Our commitment to color is an extension of the level of service we aspire to provide to you. That’s why we’ve invested in cutting-edge color technology to ensure not only excellent color but the right color, every time.

COLOR

Management

Your colors are a big part of your identity. Having color consistency on every package, on every substrate, and through every run isn’t a matter of being nitpicky, it’s a quality standard that is central to maintaining the integrity of your brand.

When it comes to Color Management, not all providers are created equal and we don’t take color lightly. Our commitment to color is an extension of the level of service we aspire to provide to you. That’s why we’ve invested in cutting-edge color technology to ensure not only excellent color but the right color, every time.

Color Lock At Your Service

The DWP Color Lock System features the latest technology in color analysis with on-press monitoring. Color Lock allows our team of experienced color specialists to use empirical data within the workflow to deliver consistent color throughout all of your projects and ensure repeatable color time after time.

Our exacting Color Lock Color Management System delivers extremely accurate color matches with unrivaled consistency. It begins with the analysis of an agreed upon color standard. Whether it is pulled from Pantone Live or created from your favorite shirt, Color Lock will build a database of the colors' components that are used to create the matched ink. Our training and workflow ensure that, as we develop the ink colors, the formulation is locked in for future runs, assuring you that your product’s colors will look the same every time you order.

Our specialists verify that our Delta-E readings meet the highest industry standards, all the while managing everything from ink density and opacity to illumination and metamerism. This level of analysis is vital to creating accurate, consistent, and repeatable colors needed for your brand and products.

Certifications in Printing

GMI Graphic Measures International

Certifies and measures the performance, processes and print quality of a printer. This assures brand owners will receive repeatable color consistency.

The G7 Method

The G7 Method is a printing procedure used for visually accurate color reproduction by putting emphasis on matching grayscale colorimetric measurements between processes.

See all of Doran & Ward's Certifications

Contact Doran & Ward Packaging

Got a question, idea or vision? We want to hear about your packaging needs! Our team of experts is at your service and we can help you find the right solution. Fill out the form or give us a call.